In our continuous effort to enhance your manufacturing operations, we’re excited to announce a game-changing addition to our Platform: comprehensive barcode scanning with automated photographic capture. This new feature marks a significant step forward in achieving seamless traceability and data capture in your production processes.

Our latest update brings universal compatibility with industry-standard barcode scanners, including popular manufacturers like Symbol, Zebra, and Honeywell. Whether you’re working with traditional 1D barcodes, advanced 2D matrices, or QR codes, our platform now handles them all with remarkable efficiency.

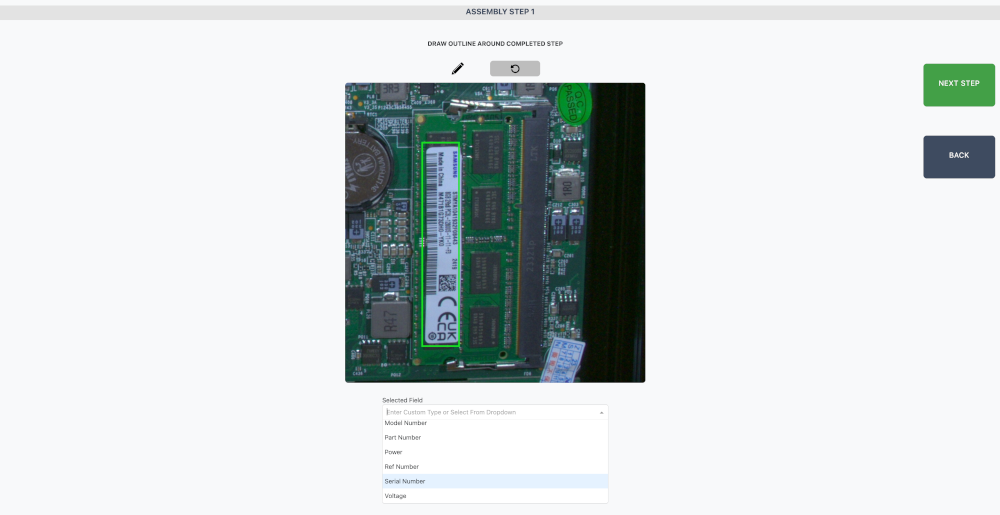

What makes this integration particularly powerful is its deep connection with digital assembly reporting. Every scan automatically populates critical data fields in your reports – from essential part numbers and serial numbers to lot codes. But we didn’t stop there. Each scan triggers automatic photographic evidence capture, creating an unbreakable chain of documentation that proves invaluable during audits, FRACAS investigations, and 8D reports.

For those operating in regulated industries, we understand that compliance isn’t optional – it’s essential. That’s why we’ve engineered this system to meet and exceed the rigorous standards set by regulatory bodies including the FDA, NTSB, and FAA. This means you can focus on your operations while having confidence in your compliance status.

This integration represents more than just a new feature – it’s a commitment to making your manufacturing processes more efficient, accurate, and traceable. By bridging the gap between physical components and digital documentation, we’re helping you build a more connected and reliable production environment.