Every manufacturer knows the sinking feeling: A major customer calls to report missing components in a shipment. Maybe it’s mounting hardware for an aerospace assembly. Perhaps it’s a critical adapter for medical equipment. Or installation tools for industrial machinery.

The immediate cost is clear – rush shipping replacement parts, processing returns, managing complaints. But the hidden costs run much deeper: damaged customer relationships, negative reviews, quality audits, and in regulated industries, potential compliance violations with hefty penalties.

One missing component can unravel months of careful production planning and years of reputation building.

The Challenge of Manual Part Verification

Traditional quality control relies on human operators to verify parts against printed checklists or work instructions. Despite best efforts, this approach faces inherent limitations:

Visual Fatigue: After hours of inspections, even experienced operators can miss small components or incorrectly count quantities.

Training Gaps: New operators need extensive training to recognize all part variations, leading to inconsistent quality during workforce transitions.

Documentation Burden: Manual verification leaves limited audit trails, making it difficult to trace when and how errors occurred.

Scaling Limitations: As product complexity increases and SKU counts grow, manual verification becomes increasingly unreliable and expensive.

The industry has long accepted a certain error rate as inevitable. But what if it wasn’t?

Introducing Part Verification Agents: Your 24/7 Quality Guardians

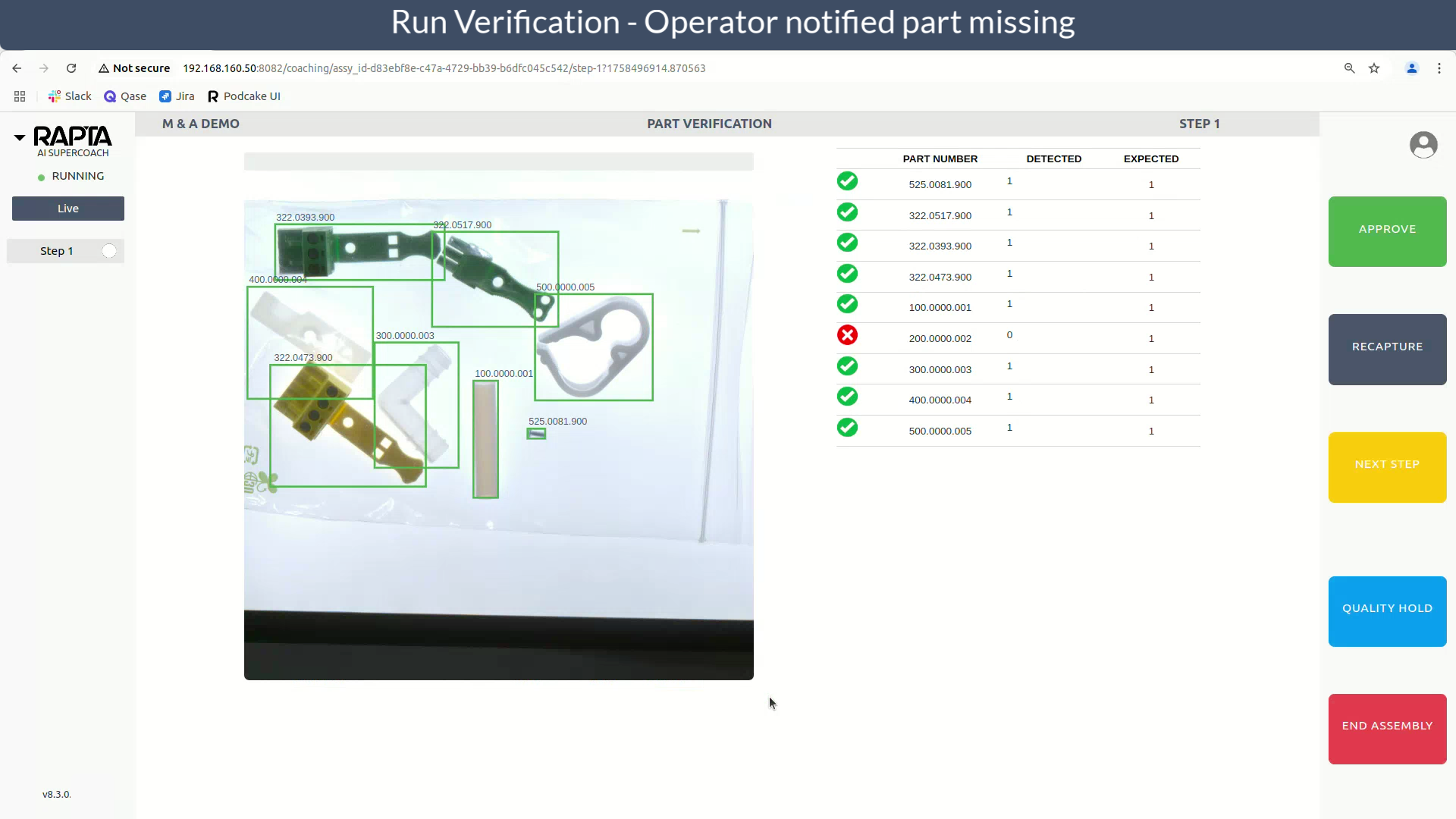

Rapta’s Part Verification feature represents a fundamental shift in how manufacturers ensure shipment completeness. Using advanced computer vision and AI, our automated agents provide consistent, accurate verification at production speed.

1. Visual Intelligence at Scale

Our AI agents learn to recognize parts from multiple angles and in varying lighting conditions. Unlike human inspectors who might struggle with similar-looking components, the system maintains high accuracy whether verifying 10 parts or 10,000.

The technology adapts to real-world manufacturing conditions: parts scattered on work surfaces, components in different orientations, and varying packaging configurations. This flexibility means minimal changes to existing workflows while maximum impact on quality.

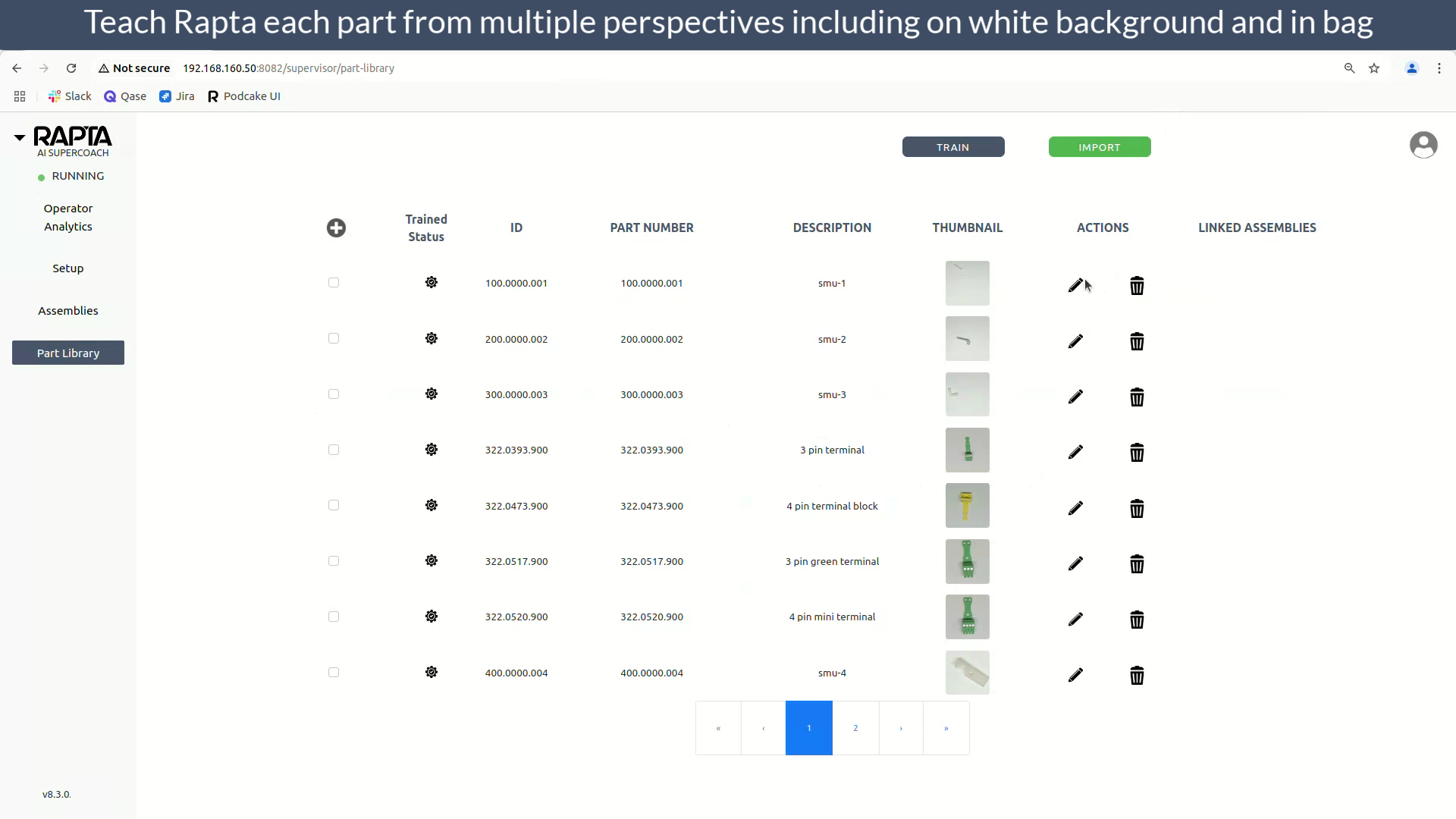

2. Continuous Learning

Manufacturing teams can build comprehensive part libraries in hours rather than weeks. Simply photograph each component from multiple angles, and the system handles the rest.

3. Seamless Integration with Existing Processes

Part Verification doesn’t operate in isolation. It integrates with Rapta’s complete quality ecosystem, creating comprehensive quality gates throughout production:

- Work Instructions: Operators see real-time visual guidance for part selection

- Data Capture: Automatic logging of work orders, serial numbers, and timestamps

- Traceability: Photographic evidence of every verification for audit compliance

- Analytics: Identify patterns in errors to address root causes

Implementation: Easier Than You Think

Getting started with Part Verification follows a straightforward path:

Step 1: Part Library Creation

Photograph your components and build your digital library. Our platform guides you through optimal capture techniques for maximum accuracy.

Step 2: Assembly Configuration

Define part quantities for each product configuration. Set up verification rules for different SKUs or customer requirements.

Step 3: Production Deployment

Roll out across all relevant production lines. Monitor performance through real-time dashboards and continuous improvement metrics.

Beyond Error Prevention: Strategic Advantages

While eliminating shipping errors is the immediate benefit, Part Verification delivers strategic advantages that extend throughout the organization:

Customer Trust: Consistent, perfect shipments build customer confidence and reduce the need for incoming inspections at customer sites.

Competitive Differentiation: In industries where quality is paramount, guaranteed shipment completeness becomes a powerful selling point.

Workforce Empowerment: Operators focus on value-added activities rather than repetitive checking, improving job satisfaction and retention.

Data-Driven Insights: Verification data reveals patterns about supplier quality, process efficiency, and training effectiveness.

The Future of Manufacturing Quality

As manufacturing complexity continues to increase and customer expectations rise, manual quality control becomes increasingly untenable. Part Verification represents the future – where AI agents work alongside human operators to achieve previously impossible levels of quality and consistency.

The question isn’t whether to adopt automated part verification, but how quickly you can implement it to protect your brand and delight your customers.