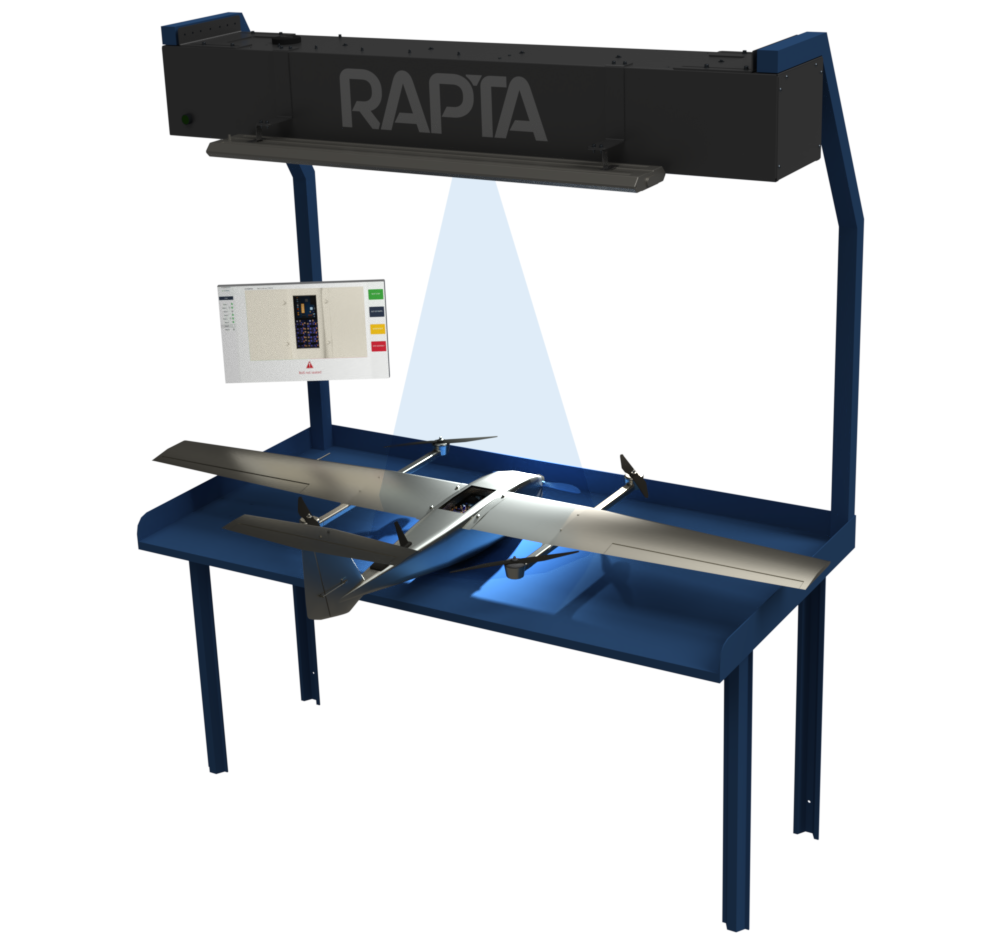

Automated Robotic Inspection Systems

Rapta offers a family of smart robotic inspection systems called the SuperPod™ for small to large precision assemblies spanning microns to meters. The SuperPod™ enables automatic inspection of areas up to 25 feet with cutting-edge AI technology that eliminates defects and automates QA. The SuperPod™ is available in cleanroom-compatible models, making it suitable for even the most stringent manufacturing environments.

10X FASTER INSPECTION

FULLY AUTOMATED ROBOTICS

98% ERRORS ELIMINATED

CLASS 1000 CLEANROOM RATED

Eliminate Defects and Automate QA Inspection

The AI SuperPod™ integrates cutting-edge technology to help manufacturers gain 30% more capacity by eliminating 98% of errors. The SuperPod™ is perfect for automating QA during or post assembly augmenting your quality inspectors and managers and unloading them from repetitive tasks. With its advanced robotic architecture, the SuperPod™ delivers inspection from microns to meters.

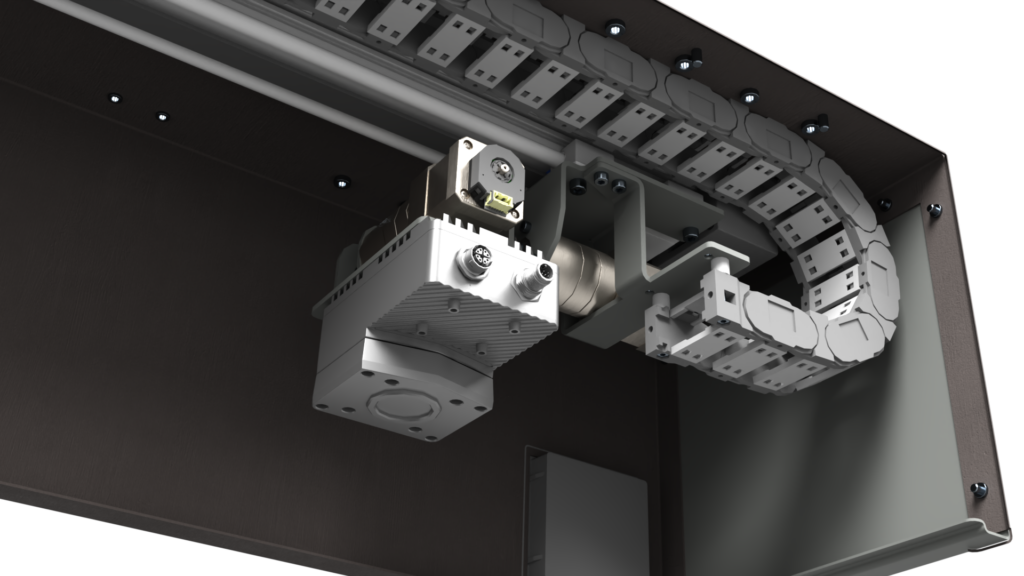

Flexible Architecture

Our Robotic Inspection SuperPod™, available in 3-axis or 4 axis variants, can cover areas up to 25 feet long with larger assemblies covered by multiple SuperPod™ stations linked together.

Configuration Options:

3-axis: 1 Linear Axis & pan / tilt camera

4-axis: X & Y linear axis & pan / tilt camera

Technical Specification

Integrations: Works out of the box with our AI Supercoach Software Platform

Accuracy: +/-0.1mm linear position

Standard Size:

3-axis: 6ft x 1ft x 1ft OR 4-axis: 6ft x 4ft x 1ft

Industrial temp rating: 32°F to 125°F ambient operating temperature

Fully enclosed and safe for any environment.

Cooling: Forced filtered air

Power consumption: 120VAC / 230VAC single phase, 240W

Applications

Schedule Demo

Discover how the SuperPod™ can transform your precision manufacturing and get in touch to discuss your application needs.