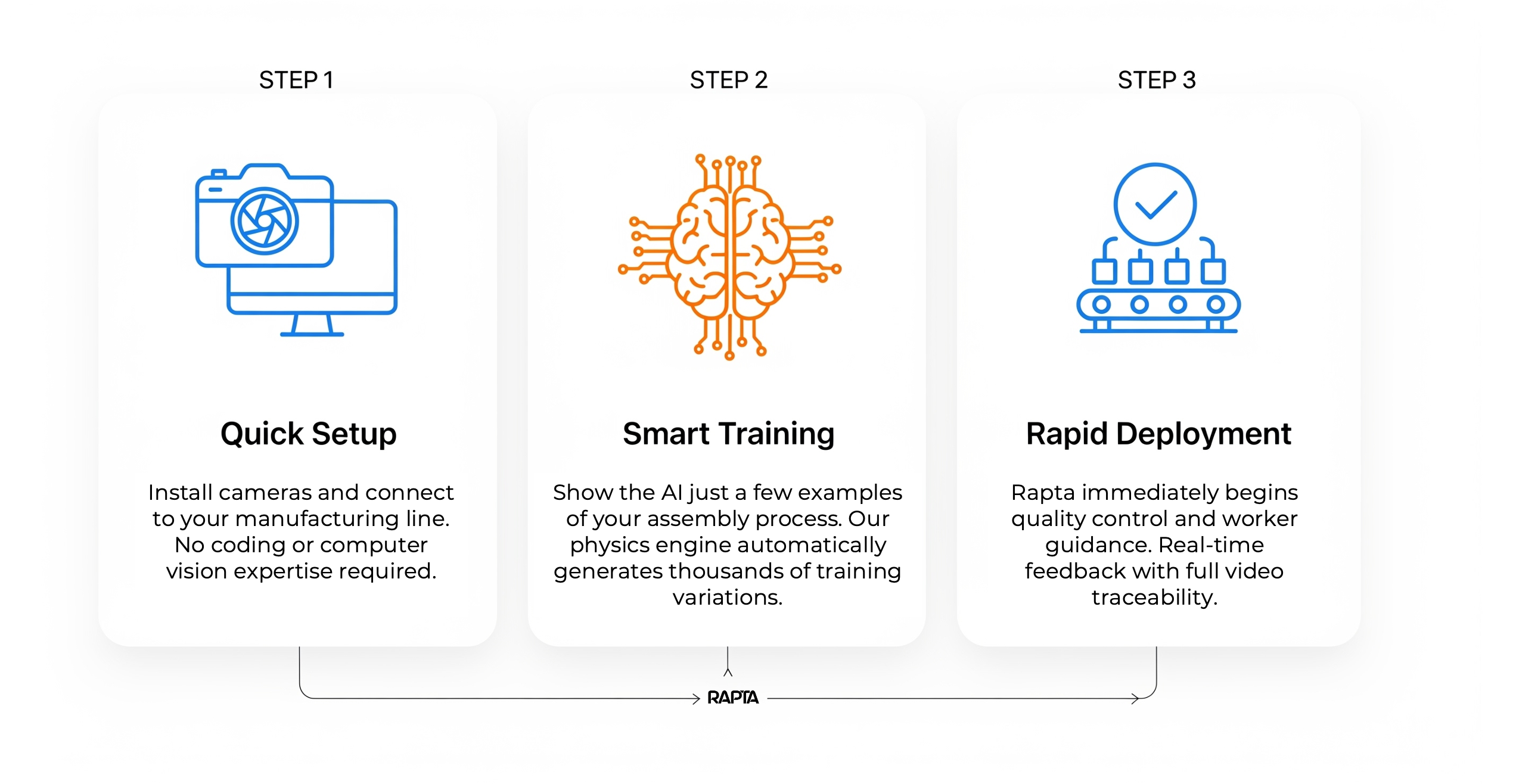

How it Works

Rapta’s highly configurable AI platform delivers rapid ROI by eliminating 98% of errors and automating workflows 10x faster. Through our intuitive visual setup tool, our platform learns your proprietary assembly techniques from just a few correct and incorrect examples. We automatically generate the AI training set in just a few minutes including augmentations to accommodate varying lighting, color and physical geometry. This approach contrasts starkly to traditional vision systems, which take months to train and require thousands of manually captured images and skilled engineering labor to achieve similar results.

Prompt based physics engine enables 100x faster deployment

Our sophisticated physics engine rapidly generates thousands of photorealistic images from powerful text prompts saving you significant time in training production grade AI models. The physics engine understands the properties of materials and manufacturing processes, allowing it to create realistic images for correct and defective parts. For example, you can simply prompt Rapta “phone screen with cracked display” and the engine will generate thousands of physically accurate images with cracks overlaid on your images based on material stress patterns and realistic failure modes.

Case Studies

Real-World Applications

Schedule Demo

Get a virtual demo of Rapta and see how we can help your manufacturing organization.