High Value Kitting and Part Counting

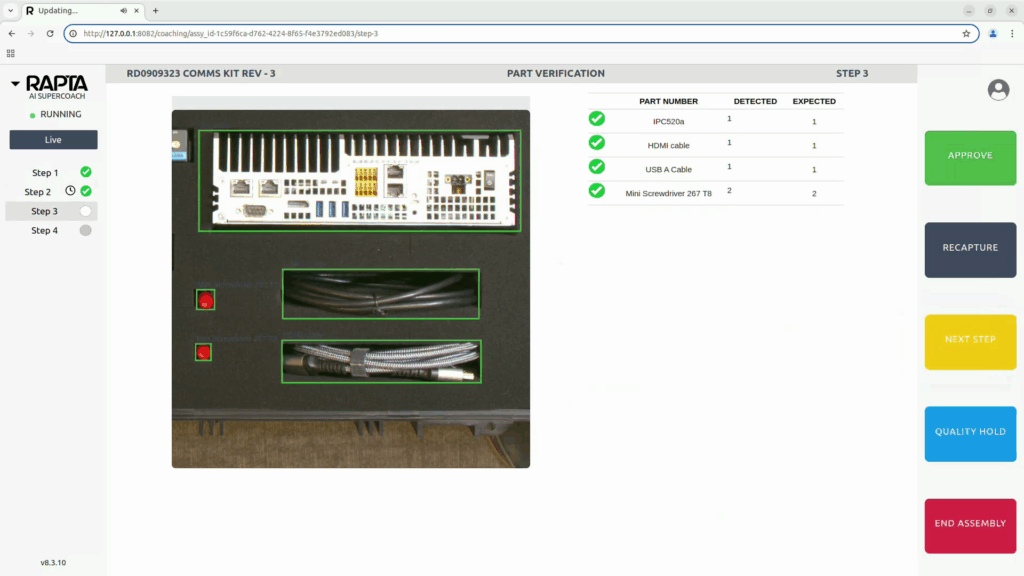

Rapta’s Part Verification feature uses high accuracy vision systems to automatically identify and count components during critical manufacturing checkpoints. Whether validating kitted parts before assembly, verifying piece counts in production totes, or confirming final packed products before shipment, the system compares what’s actually present against expected specifications in real time. This eliminates the manual counting and visual inspection processes that are both time-consuming and prone to human error—especially when dealing with high-mix assemblies or components that look similar.

In Process Verification

The value of automated kit verification extends throughout the production workflow. Missing or incorrect parts caught at the kitting stage cost pennies to fix; the same error discovered at final assembly or, worse, by a customer can cost thousands in rework, scrap, and expedited shipping. By integrating verification at multiple touchpoints—from incoming part counts to tote staging to final pack-out—manufacturers establish quality gates that prevent defects from propagating downstream.

Complete Traceability

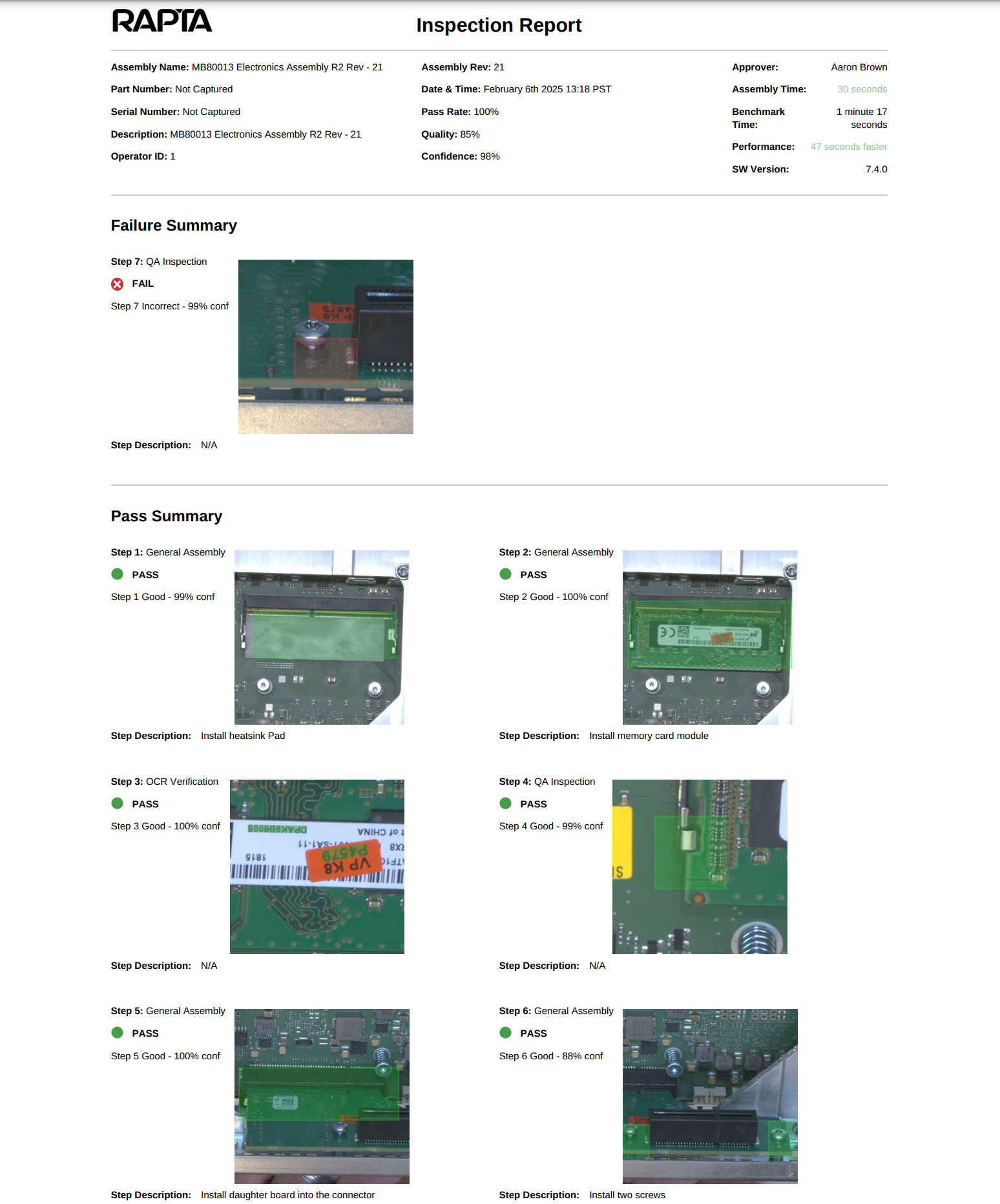

Assembly Report with Photographic Traceability seamlessly integrates serial number, part number, date code and batch number tracking, ensuring meticulous documentation and comprehensive oversight at every step of the manufacturing process. With photographic traceability, each component’s journey from inception to assembly is visually recorded, offering clear insights for quality control and assembly accuracy. All reports can be archived for long term storage to meet regulatory requirements of various governmental bodies including NTSB, FDA, DOE, NHTSA and more.

Schedule Demo

Get a demo of Rapta and see how we can help your manufacturing organization.