Our AI Platform automates inspection processes previously performed by human workers ensuring the highest possible first pass yield.

Quality Assurance

Rapta rapidly learns key aspects of the production process from torqued screws, washers, nuts, bolts through to connectors, wires and cable retention points. Our customers yield a quick Return on Investment with QA mode by taking engineers out of the inspection process and increasing first pass yield by inspecting at key points throughout the assembly line.

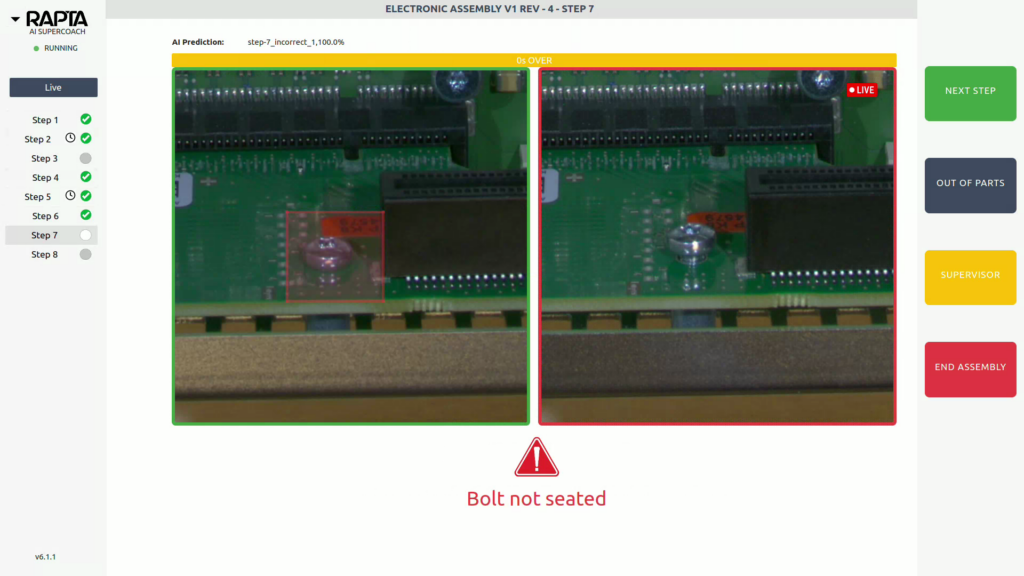

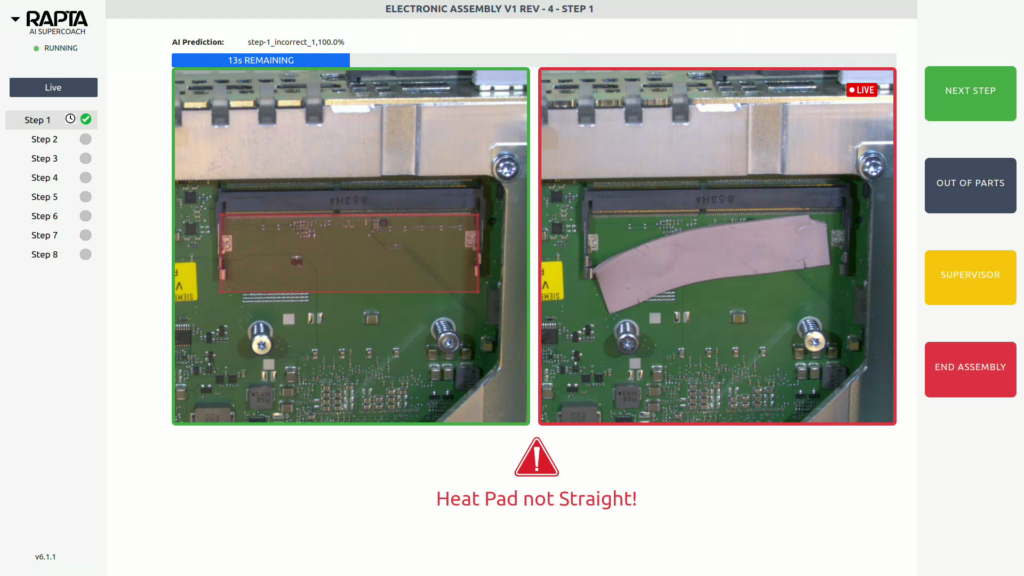

In Process Verification

Rapta ensures humans don’t make errors by checking their work in real time and detecting defects that require immediate repair. This saves significant costs in rework or field failures due to manual process errors.

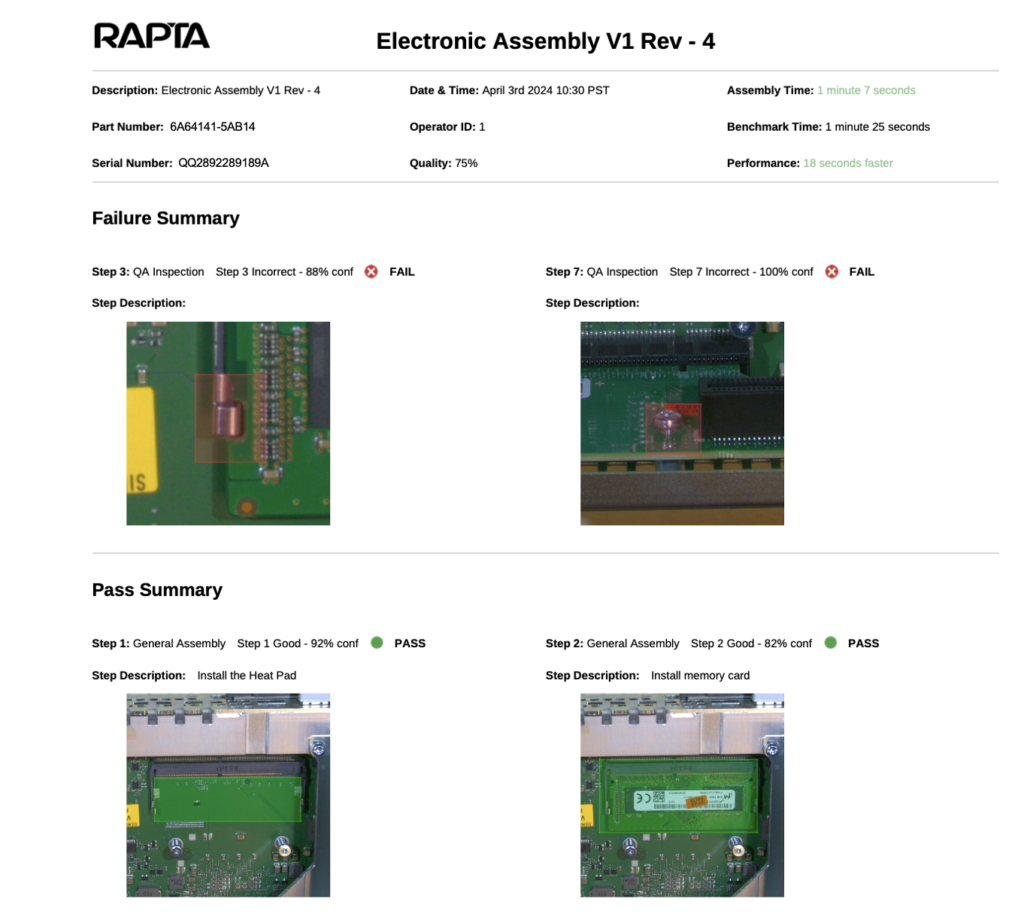

Comprehensive Reporting

Assembly Report with Photographic Traceability seamlessly integrates serial number, part number, date code and batch number tracking, ensuring meticulous documentation and comprehensive oversight at every step of the manufacturing process. With photographic traceability, each component’s journey from inception to assembly is visually recorded, offering clear insights for quality control and assembly accuracy. All reports can be archived for long term storage to meet regulatory requirements of various governmental bodies including NTSB, FDA, DOE, NHTSA and more.

Learn More

Get a virtual demo of Rapta and see how we can help your manufacturing organization.