Configuring Alignment AI

Feature supported from V7.5.0

Alignment AI is an advanced computer vision AI model that enables real-time tracking and alignment with assembly components in manufacturing environments, eliminating the need for fixed fixtures during the manufacturing process.

Core Functionality

The system employs deep learning algorithms to identify and track target components within the camera’s field of view. Once trained on a component’s physical characteristics, it maintains continuous tracking regardless of position changes or movement.

Key Capabilities

Dynamic Target Tracking

- Real-time component recognition and tracking

- Continuous alignment updates during the manufacturing process

- Adaptive field-of-view adjustment

- Position-independent quality verification

Tolerance Management

The system accommodates standard manufacturing variations while maintaining accuracy through:

- Dynamic position compensation

- Real-time spatial adjustment

- Automatic recalibration during movement

- Variable tolerance thresholds

Hardware Compatibility

- Compatible with our supported industrial cameras.

- Minimum camera resolution: 8MP to 12MP recommended.

- Lighting requirements: Refer to our lighting best practices guide.

Configuration Guide

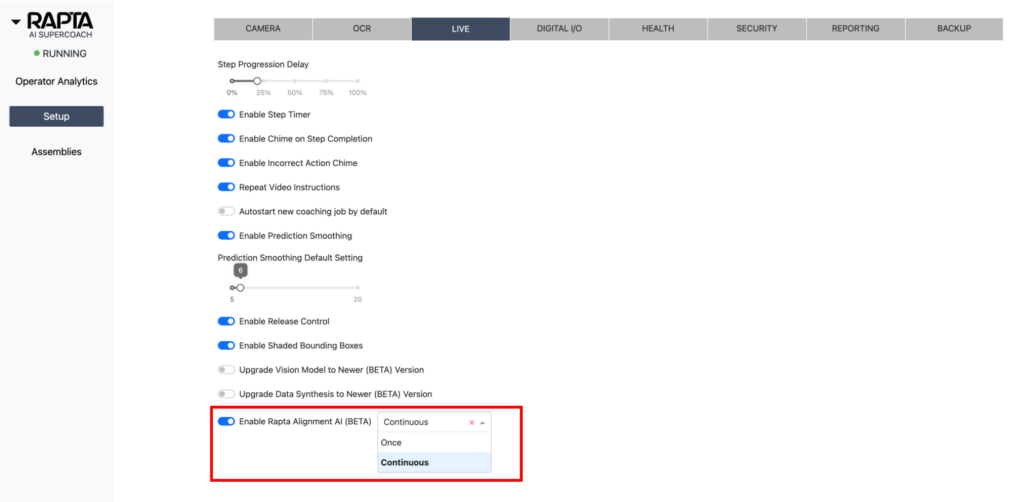

Alignment AI is enabled from the LIVE setup menu by enabling the toggle for Alignment AI, highlighted below. The modes of Operation are as follows:

- Continuous: Alignment AI continuously aligns the camera feed to the first correct trained images for each specific step in your assembly.

- Once: Alignment AI aligns the camera feed only once at the start of each step.

This feature can be disabled by switching the toggle off.