Installing a Torque Wrench: Modbus TCP

Our AI Platform supports the connection of the Kolver K-ducer torque wrench family by Modbus TCP.

Supported Release

This feature is supported from version 7.8.0 of the Rapta AI Platform.

First Verify Kolver Firmware Version

Ensure your wrench is running firmware v38, we do not currently support other versions of the Kolver firmware.

Configure the Kolver IP Address

To configure a Kolver K-Ducer’s IP address, access the device’s settings menu through its control interface, typically using a web browser, and navigate to the network settings section where you can directly input the desired IP address, subnet mask, and gateway information for your network; consult your Kolver K-Ducer manual for specific instructions on accessing the configuration menu and setting the IP address. Refer to manual for detailed instructions.

Torque Wrench Settings to Adjust:

- Protocol: Modbus TCP

- DHCP: OFF

- IP Address: 192.168.86.120 [Note: If you have multiple Kolver torque wrenches on the same Rapta network, ensure that the second wrench is 192.168.86.121, etc]

- Subnet Mask: 255.255.255.0

- Gateway: Not required

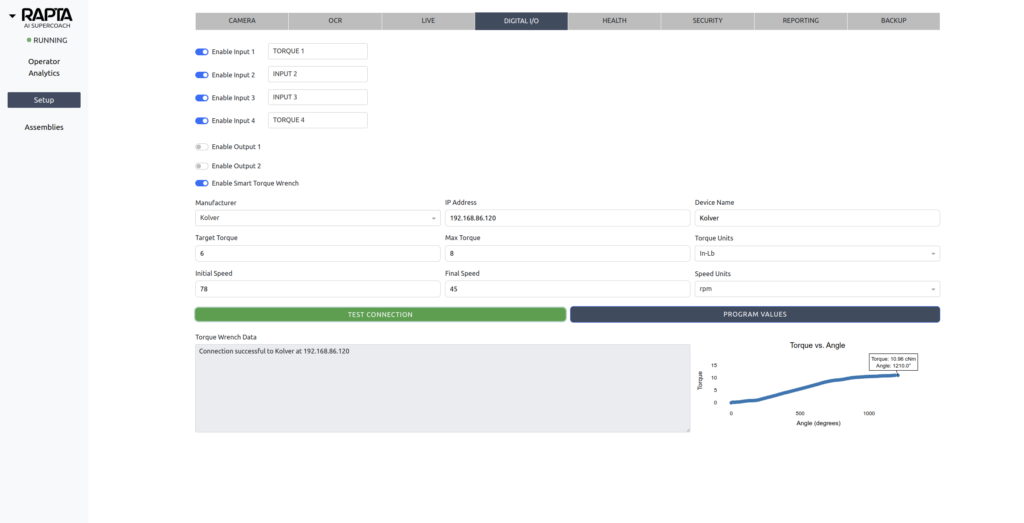

Configure the Rapta User Interface

From the Rapta UI setup menu, the Kolver smart wrench interface can be enabled and configured following this process:

- Enable the Smart Torque Wrench

- Enter the IP Address

- Press “TEST CONNECTION” to verify correct configuration

- Test values can be programmed into the wrench for the purpose of testing the wrench and trying different torque and speed settings.

- The Torque vs Angle chart will only display upon successful completion of a torque job where the torque wrench achieves its target torque and does not exceed the max torque.