How can we help?

Realtime mechanical assembly QA

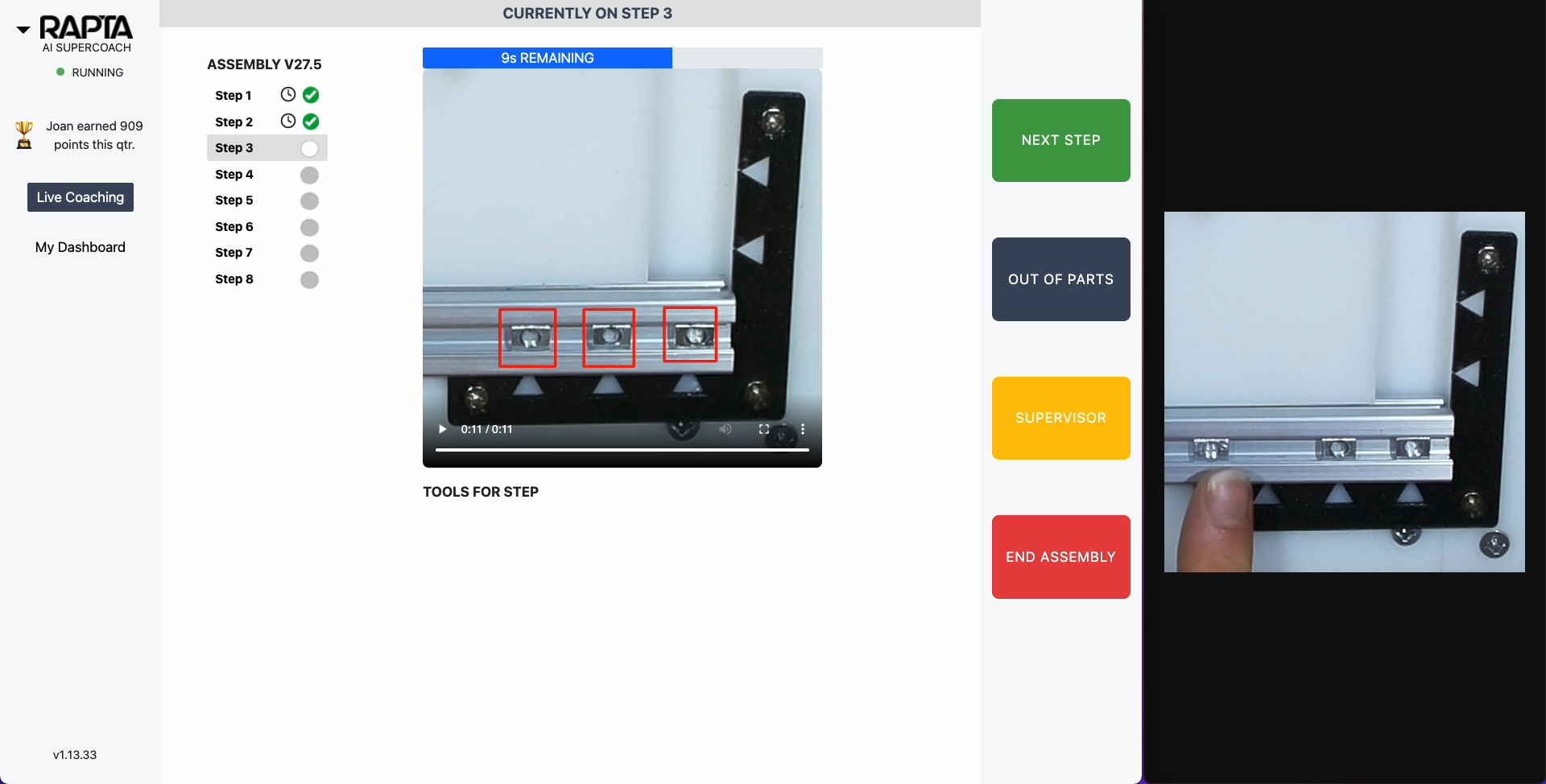

In this example you will see Rapta’s AI Supercoach guiding the assembly worker, in real time through the correct assembly steps and providing real time quality assurance by identifying defects and correct remediation. When an incorrect step is made, the red bounding box around the assembly step flashes RED indicating to the operator they have an action that needs correcting.

The major steps in this assembly process includes:

- Placing the bars into the fixture and validating correct placement.

- Placement of T-nuts in correct location.

- Installation of right angle bracket and screws.

Rapta ensures each and every one of the products you ship are correct according to your standard work instructions and we provide full video traceability for every assembly we validate.