Occlusion Augmentations

Overview

Occlusions occur when objects such as hands, fingers, hair, tools, or other items accidentally obstruct quality inspection points during the assembly process or QA checks. These obstructions can lead to inspection errors and false readings if not properly accounted for in the AI model training process. Rapta solves the occlusion challenge with an advanced approach that uses synthetic data augmentation to simulate occlusions in your dataset.

Version Support

Supported from V7.7.0.

The Challenge of Occlusions

Traditional AI systems require manufacturers to manually create datasets that include occluded scenarios, which is:

- Time-consuming and labor-intensive

- Prone to missing important occlusion scenarios

- Difficult to maintain consistency across different datasets

- Resource-intensive, requiring dedicated time from operators

Rapta’s Automated Occlusion Solution

Rapta’s AI platform features an automated occlusion generation system that eliminates the need for manual dataset creation. This innovative approach provides several key benefits:

Automatic Generation

The system automatically generates various common occlusion scenarios for each inspection step in your assembly process. This includes:

- Hand and finger obstructions

- Tool interference

- Material handling equipment

- Environmental factors

- Operator-related occlusions

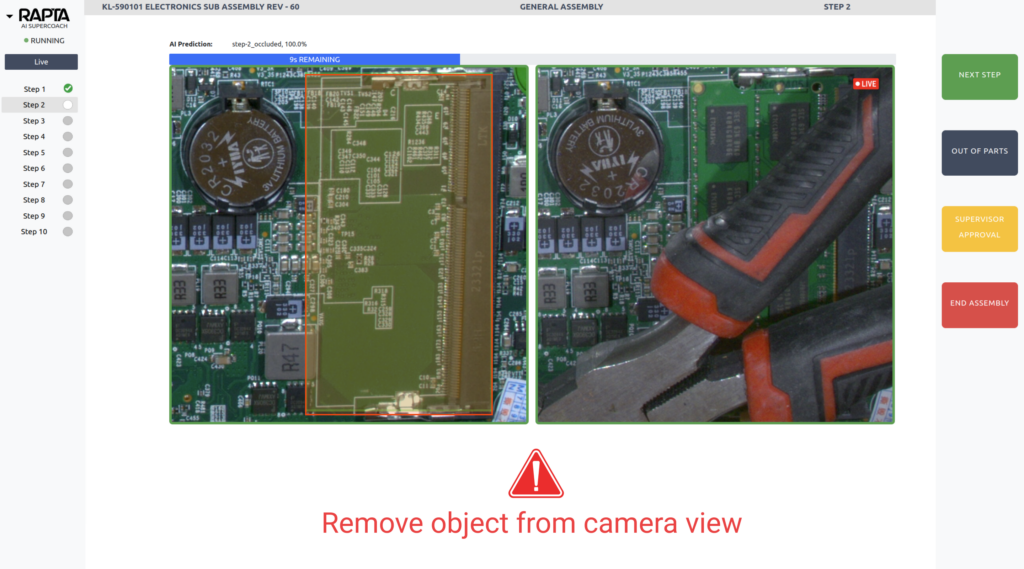

Real-time Detection

During production, the AI platform can:

- Identify when occlusions are present

- Alert operators to potential inspection interference

- Maintain quality control despite temporary obstructions

- Reduce false readings and unnecessary line stoppages

Performance Improvements

Implementation of automated occlusion handling delivers:

- 3X faster AI model creation compared to manual data capture

- Reduced training time and resource requirements

- More comprehensive coverage of potential interference scenarios

- Improved model accuracy and reliability

Technical Implementation

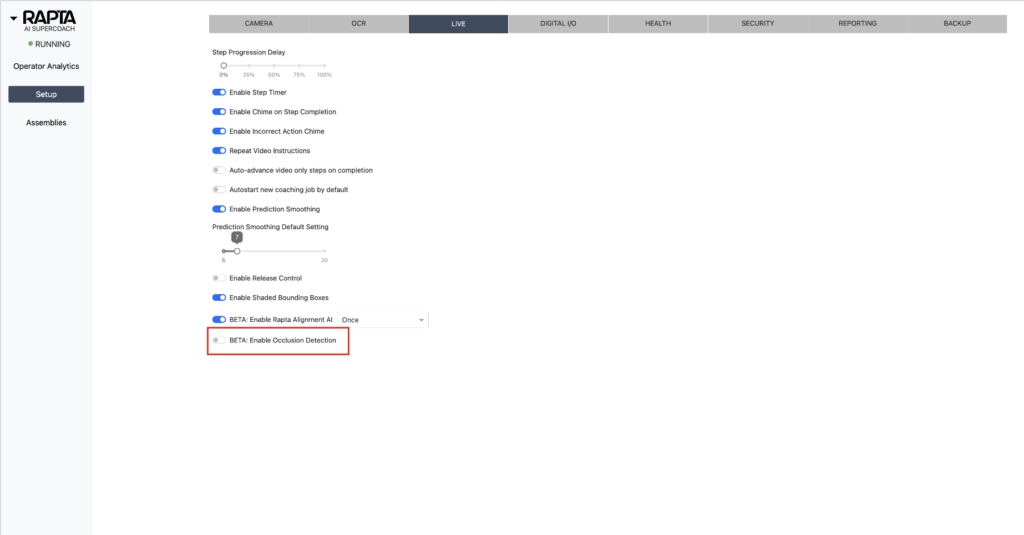

The occlusion generation system can be activated from the supervisor setup menu by following these steps:

- Enable Occlusion Augmentation from the setup tab then build your assembly

- Once activated occlusion augmentation automatically activates during dataset creation

- Requires no additional configuration

- Scales with your existing inspection points

Impact on Quality Control

Proper handling of occlusions results in:

- Reduced false positives in quality inspections by 90% or more.

- More reliable detection of actual defects

- Improved operator confidence in AI-assisted inspection

- Streamlined quality control processes