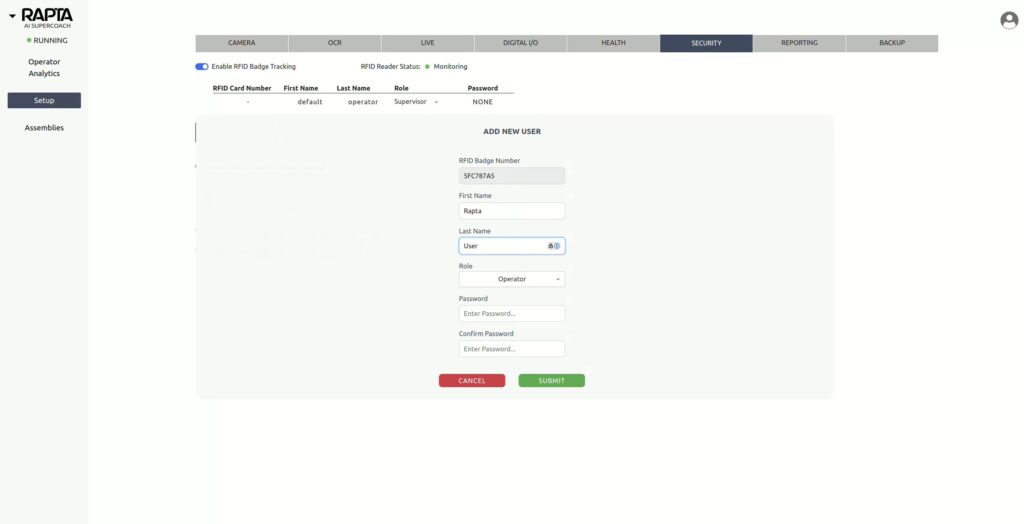

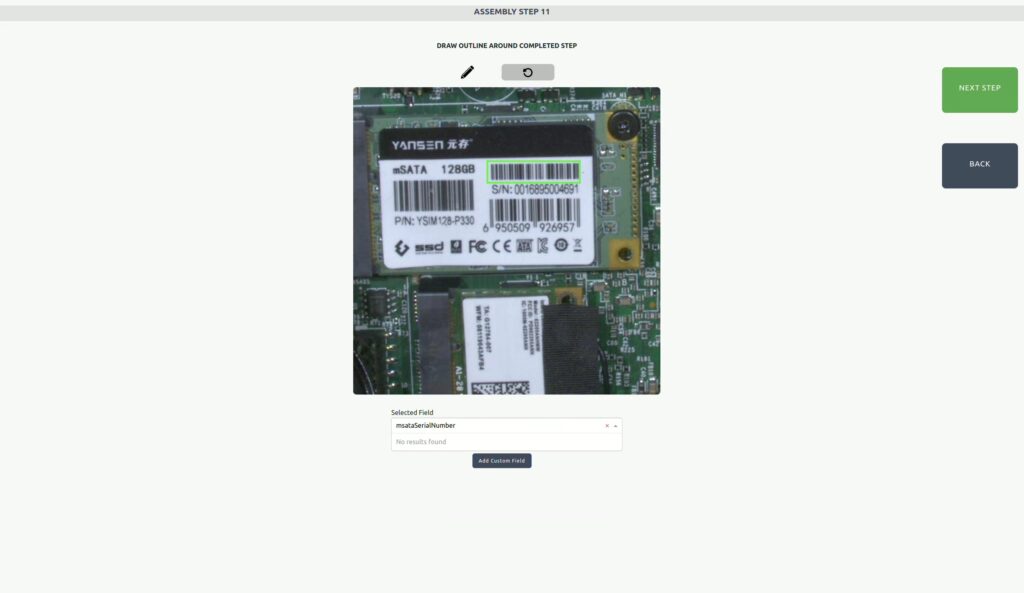

Setup Pages – Platform Configuration

From the Supervisor page, navigating to the SETUP tab on the left presents the user with multiple pages that allow for configuring the Rapta Supercoach. The following images can be viewed in printable PDF format here: RAPTA_UI_QuickReference_SETUP The following shortcut keys can be used at any time while using the Rapta Supercoach: