Archives: Knowledge Base

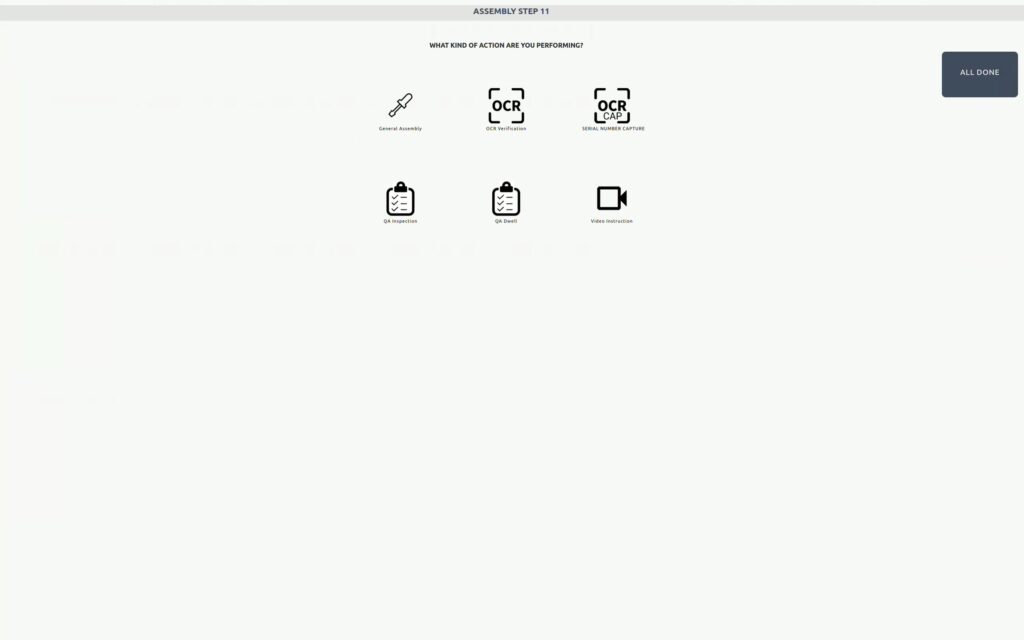

Video Instruction Action

This feature enables you to capture your critical manufacturing work processes as a video instruction that can be used in conjunction with critical automated QA checks, OCR verification, Serial Number verification and barcode capture. To create a Video Instruction Action, follow this example video:

Corning C-Mount Auto Focus Lens

This document outlines the technical specifications and implementation details for using Corning C-mount auto focus lenses with Rapta systems. Technical Specification Lens Compatibility Refer to Corning documentation for detailed system specification. System Requirements Setup Instructions Usage Guidelines: Recommended Lens Selection Large Machine Documentation Assembly Process Recording Detailed Component Inspection Troubleshooting Common Issues and Solutions Lens …

Installing an RFID Reader

Our AI Platform supports the integration of RFID readers for Supervisor login and Operator badging. We support the following RFID devices: Advantech Reader Installation Instructions Reader Specifications Installation Procedure 2. Remove rear bottom I/O cover first.3. Remove the side cover, and open the small side door on the side cover. 4. Connect module to adapter …

USB Backup Configuration

Overview Starting with version 7.3.0, users can now back up their system to a USB drive. This document provides instructions for locating the correct USB port and initiating the backup process. System Requirements Important Note The USB drive must be formatted as FAT or it will not work with the Rapta system. Recommended USB Device …

Periodic Maintenance

The Rapta system utilize long life components which typically don’t require regular maintenance. The filter and outlet fans are the only serviceable item that we recommend be replaced every 3 to 6 months depending upon the environment you operate within. Part Number: Fandis M08FPFK Source to buy the replacement filters: https://www.automationdirect.com/adc/shopping/catalog/enclosure_thermal_management_-a-_lights/filter_media/m08fpfk

Supervisor Lockout & Email alerting

As of our 7.4.0 release, we have added the ability to password protect the Supervisor & Next buttons during assembly coaching. This protection can be applied to any step type that you wish. The use of these protections can optionally be reported on via e-mail. In order to enable this feature, follow the steps below: …

Cloning Assemblies

Transform existing Assembly revisions into brand new Assemblies with our latest cloning feature. Follow these steps as a Supervisor: Step 1 Go into the Assemblies Edit page and find the ‘Clone Assembly’ button. Step 2 The tool-tip explains that this will create a new assembly that will start on revision 1 Step 3 A page …

Daily Report

The Daily Report that is received in email provides the Supervisor with a report of all the coached assemblies that happened in the previous day. The email will come with 2 attachments, a CSV with all the data that can be imported into any tool that supports CSV files that you like, and a PDF …

Inspection Report

The Inspection Report header contains a lot of information about the results for assembly jobs run in production. A detailed explanation of each field is below: Assembly Name: The name the assembly is currently given. This can be edited later. Part Number:This is the Part Number that was captured during the OCR Serial Number Capture …