Best Practices for Creating an Assembly

This guide covers best practices for creating a new assembly.

Lighting

Refer to our setup guide Correct Lighting Setup

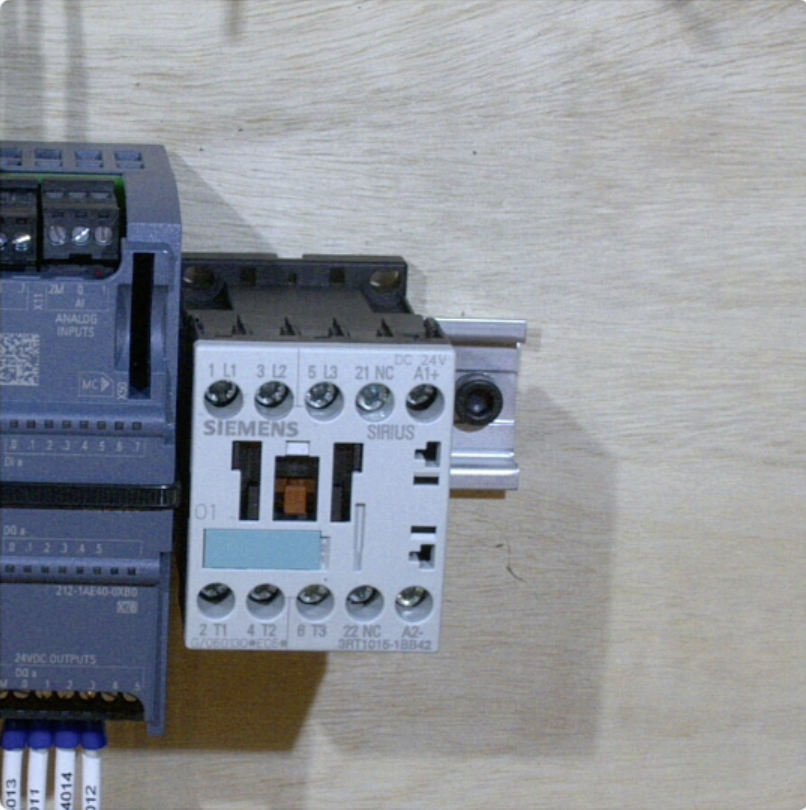

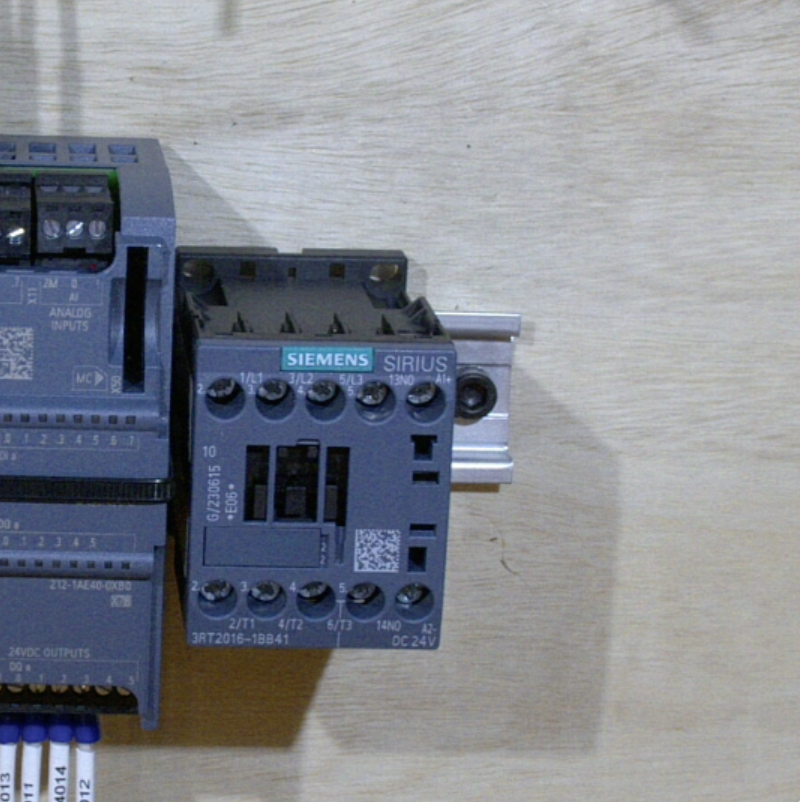

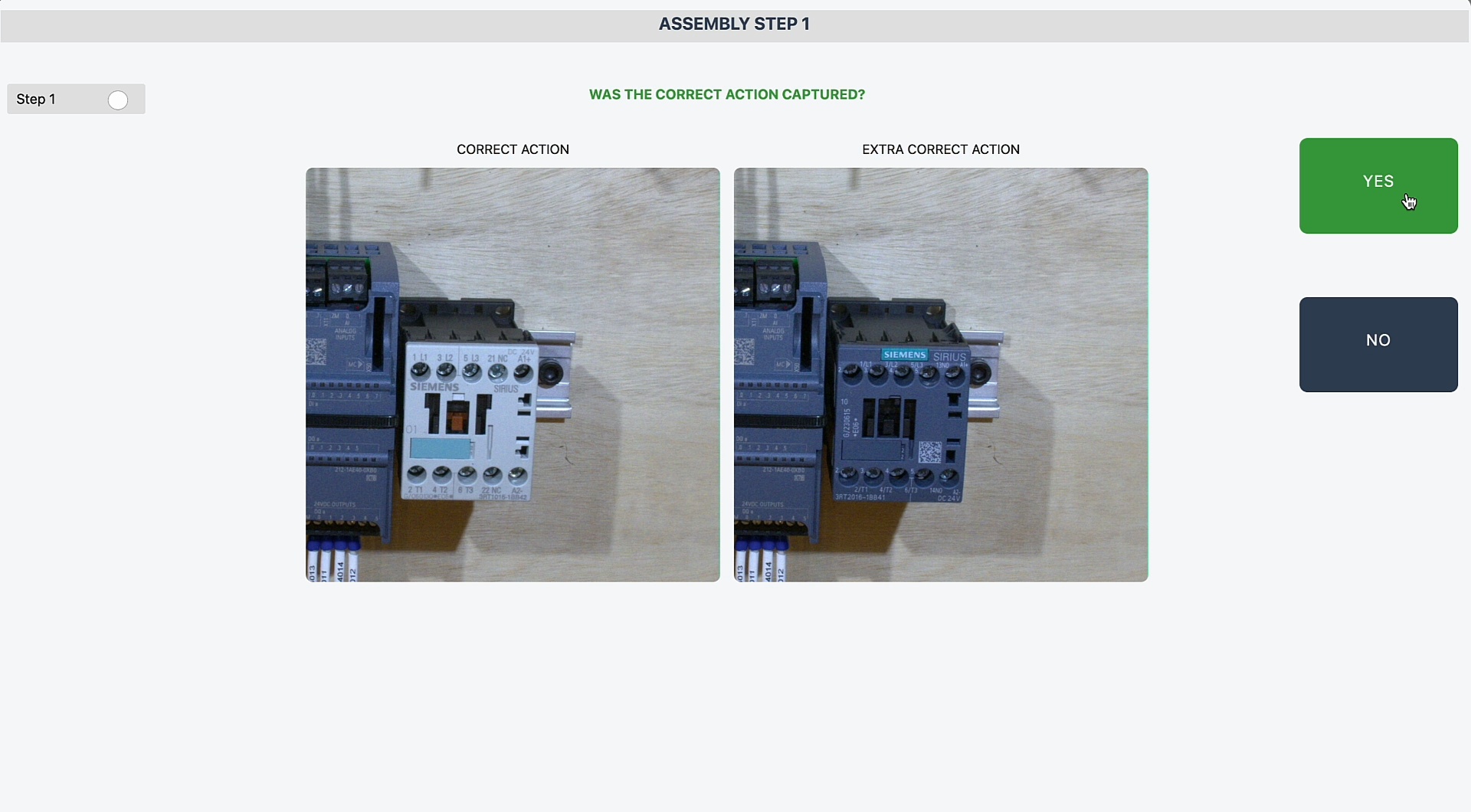

Correct Step Examples

Our AI platform can be trained to recognize multiple different good images of the same QA and Assembly step. This is critical when a component may be substituted or if the part is expected be undergo QA from multiple different perspectives.

In this video you will see how we can navigate the software to create multiple correct examples for a specific step:

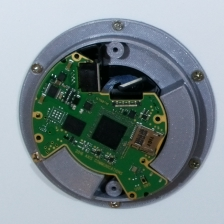

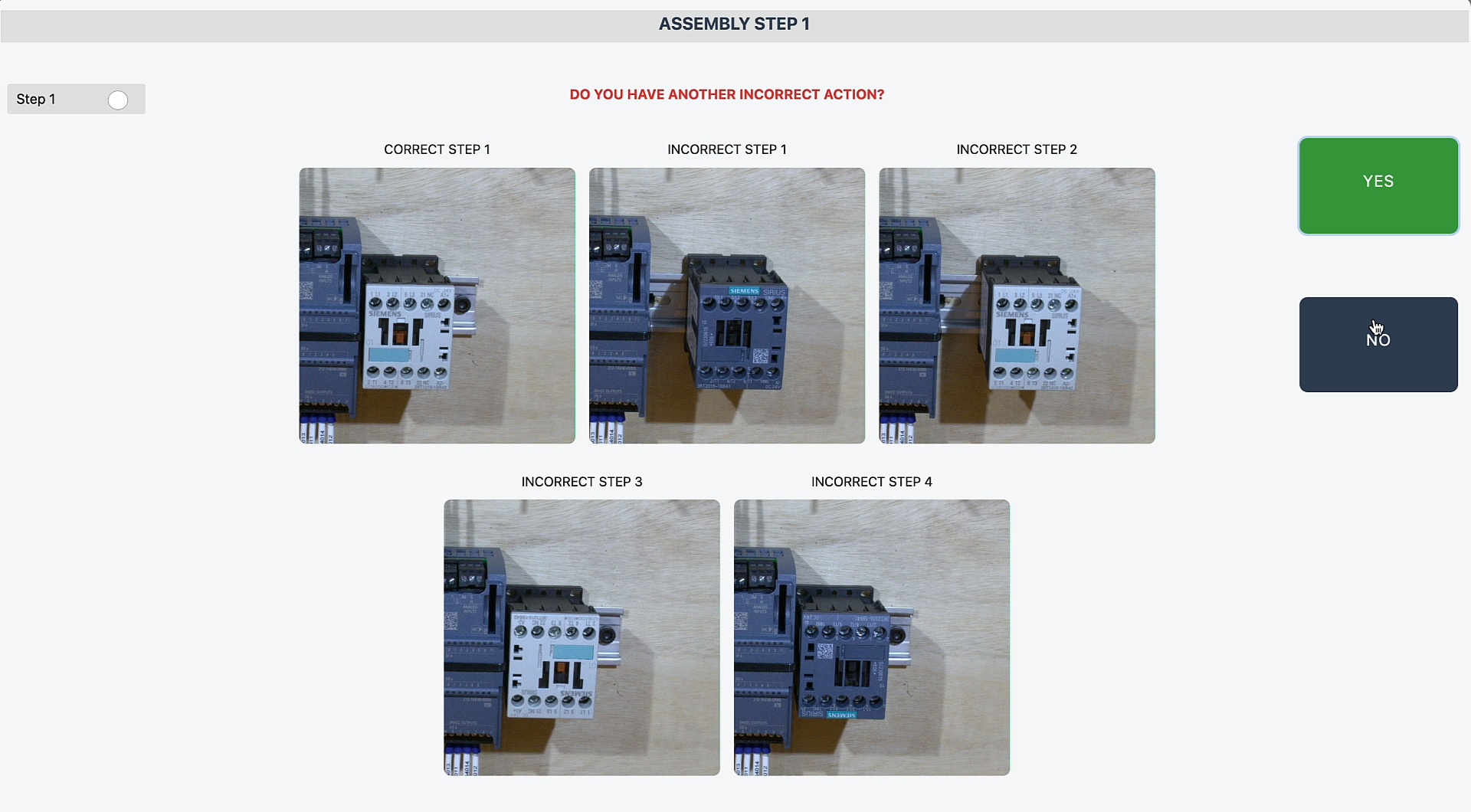

Incorrect Step Examples

Our AI platform performs best when incorrect steps are provided as part of the assembly creation process. Incorrect steps help the AI model understand your unique assembly requirements and adapt to catch issues you commonly see on the manufacturing floor. Incorrect steps are added after the correct version of a step is performed in the assembly creation process. Below is an example of incorrect steps added during the PCBA installation process:

In this video you will see how we can navigate the software to create multiple incorrect examples for a specific step:

Data Augmentation Adjustments

The AI Supercoach automates the process of creating large, synthetic data augmentations of your original assembly images which is critical to building an AI system that can work in real world conditions. We offer the user three main forms of adjustments with the following behavior.

Lighting Adjustments

This varies the amount of brightness, contrast, lighting color temperature used in the adjustment. For maximum AI system performance we recommend setting this to the highest adjustment available.

Color Adjustments

This varies the amount of color we vary in an assembly. By default it is set to minimum. In the case where you have parts where you are looking for small color differences keep this minimal. If you are looking to generalize the AI system so it is less sensitive to color differences between parts increase this adjustment.

Placement Adjustments

This varies the zoom, rotation, and placement of your assembly in the scene to provide greater generalization for the AI system. If you desire the AI system to be more precise in the location of assembly parts reduce the adjustments to minimum, if you are seeking more flexibility in the placement adjustments, set this to max.