Installation Guide

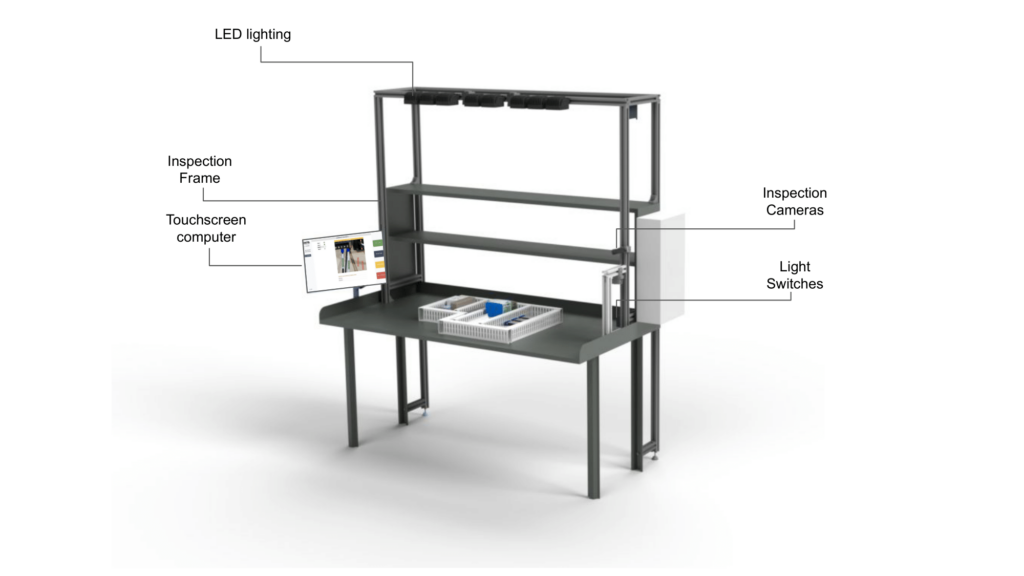

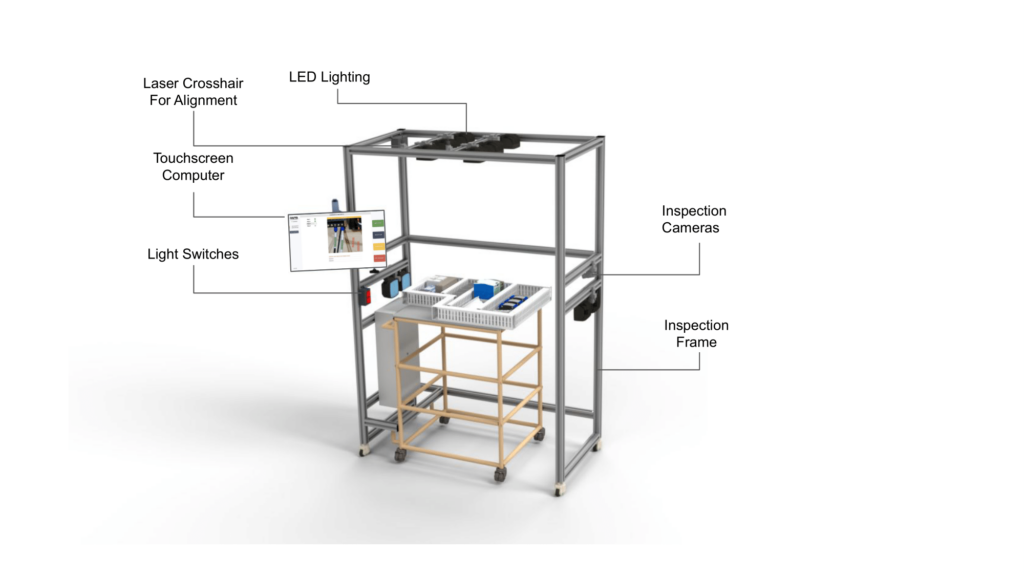

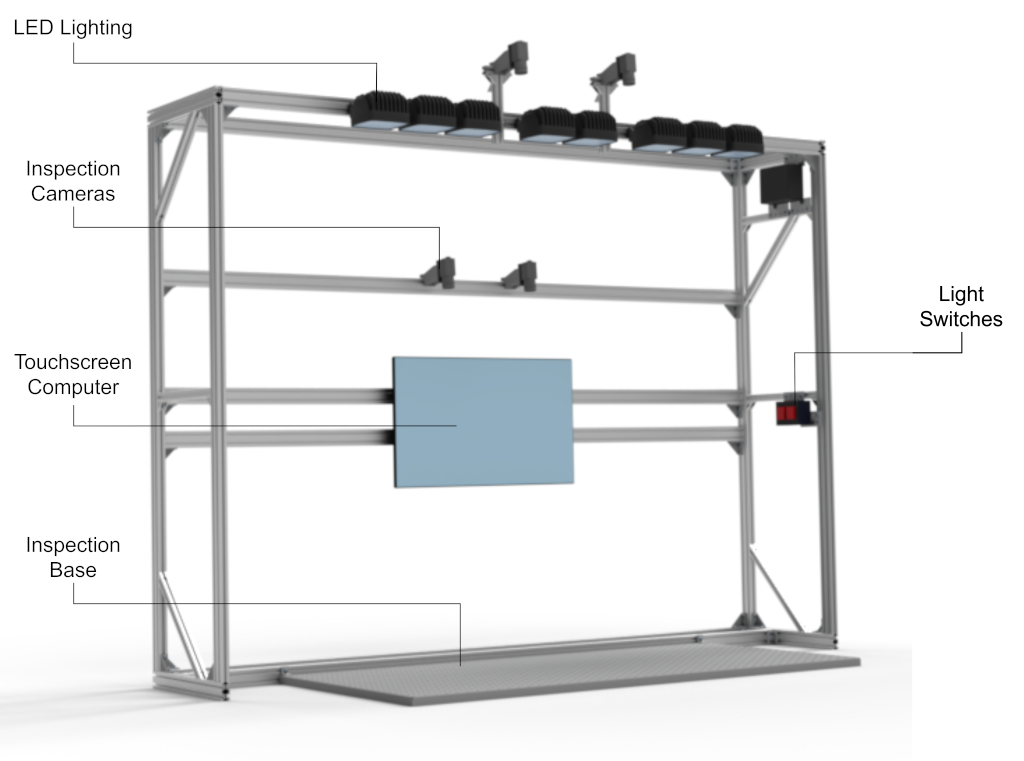

Congratulations on purchasing a Rapta AI Station. This guide will walk you through setup and installation of the system in your facility. After following the system installation, please refer to Correct Lighting Setup and Camera Setup to complete the process. The Rapta AI station bench mount stand is designed to be flexible to suit your application environment with custom width and heights available. Our stand can accomodate between one and ten high resolution camera’s with a range of different lens to match your specific application needs. Refer to our guide Camera Setup for details relating to camera and lens selection. We have customers electing to use their existing frame or fixtures, in many cases this is perfectly fine. Contact our Support Team to find out if this is compatible with the Rapta AI Inspection system.

We have several reference designs available to help you get started fast ranging from bench top work cells to cart inspection cells.

Typical installation time

This production stand can be installed in 2 – 4hrs with one to two experienced technicians.

Required tools

The following tools are required to install the production stand:

- 2.5mm Allen Key (ball end preferable)

- 3mm Allen key (ball end preferable)

- 4mm Allen key (ball end preferable)

- 6mm Allen key (ball end preferable)

- Small flat head screwdriver

- #2 Philips driver

- Needle nose pliers

- Spirit level

Assembly process

The Production Stand ships flat pack to your site and requires assembly with the minimum tools listed above. You will need to mount the Rapta stand on a sturdy workbench that is leveled on the floor. Detailed drawings ship with the production stand and are available on request, please Contact our Support Team.

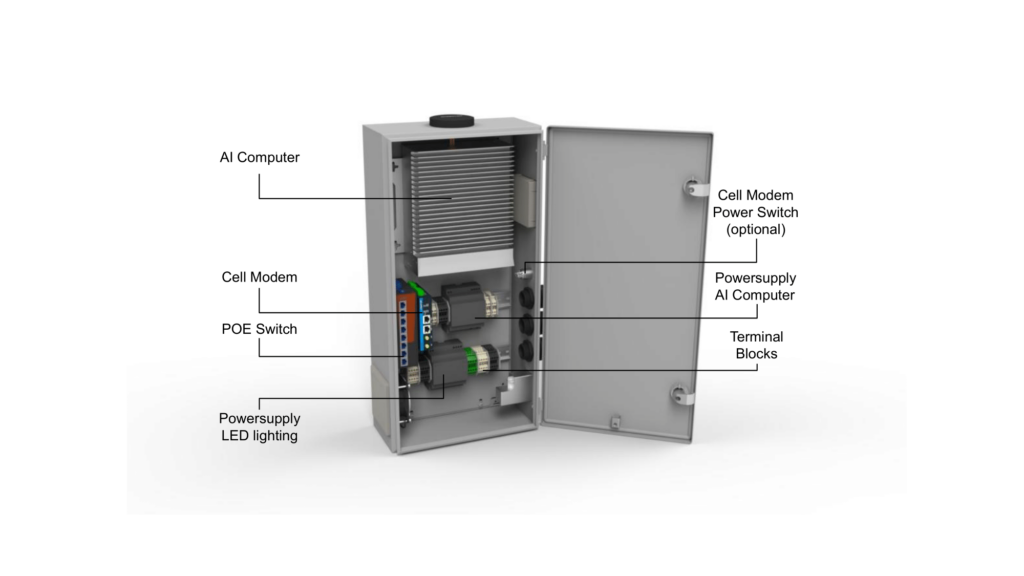

Installing the AI Computer

The AI computer comes in a ready to install, IP65 rated electrical panel with internal power supplies, network switch and other supporting hardware. We typically mount the electrical panel on the right or back side of the bench at a readily accessible service height to match your factories requirements for accessibility. The electrical panel contains two carbon filters, one in the fan and one in the outlet that should be changed every 6 months or more regularly depending upon the amount of particulates in your factories environment.

Next steps

After following the system installation, please refer to Correct Lighting Setup and Camera Setup to complete the setup process.